Kaydon bearing remanufacturing program

Our process

Initial inspection

Inspection and documentation of turning torque, free-state clearance, gear size, and external features.

Disassembly and cleaning

Bearings are disassembled and the races, rolling elements, and spacers are cleaned.

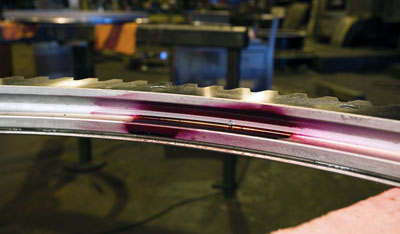

Non-destructive testing

Races undergo visual or magnetic particle inspection to detect cracks or defects. Hardness readings are recorded.

Repairability assessment

The service department reviews each bearing, application, and test result to determine repairability.

Precision grinding

Bearing races are precision-ground to the proper geometry to optimize the bearing load-carrying capability.

Assembly

The bearing is assembled with new rolling elements and seals, and packed with lubricant.

Final inspection

All critical features are inspected and documented. The bearing is approved by quality control before shipment.

Manufacture

If at any time during the process the repair does not meet Kaydon's demanding specifications, a replacement race or a new bearing can be manufactured. Mine operators can take advantage of big cost savings with our inventory of replacement mining slewing bearings.

|